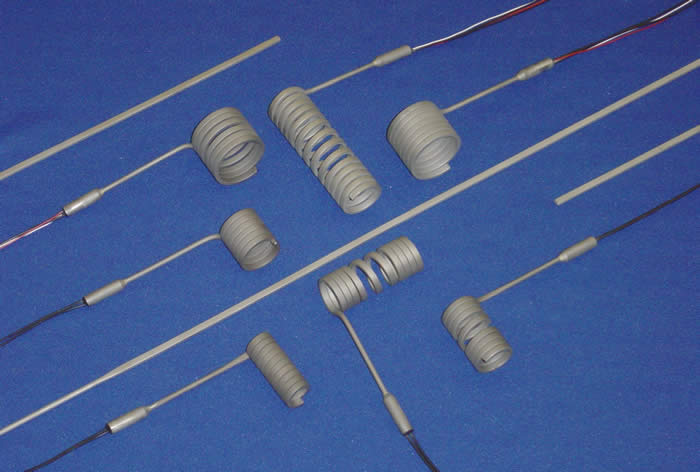

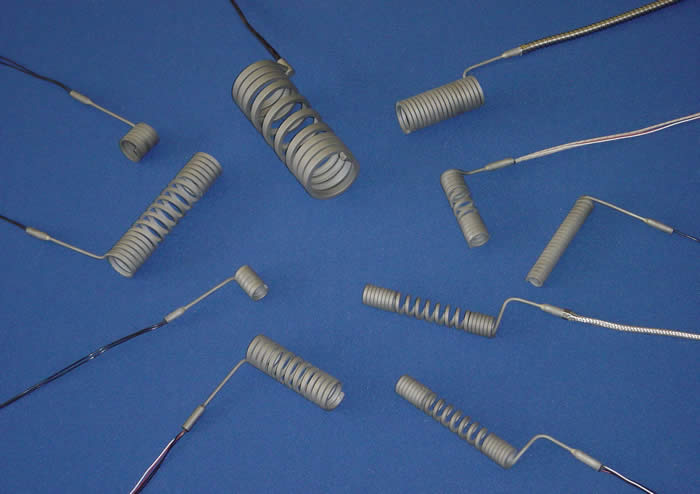

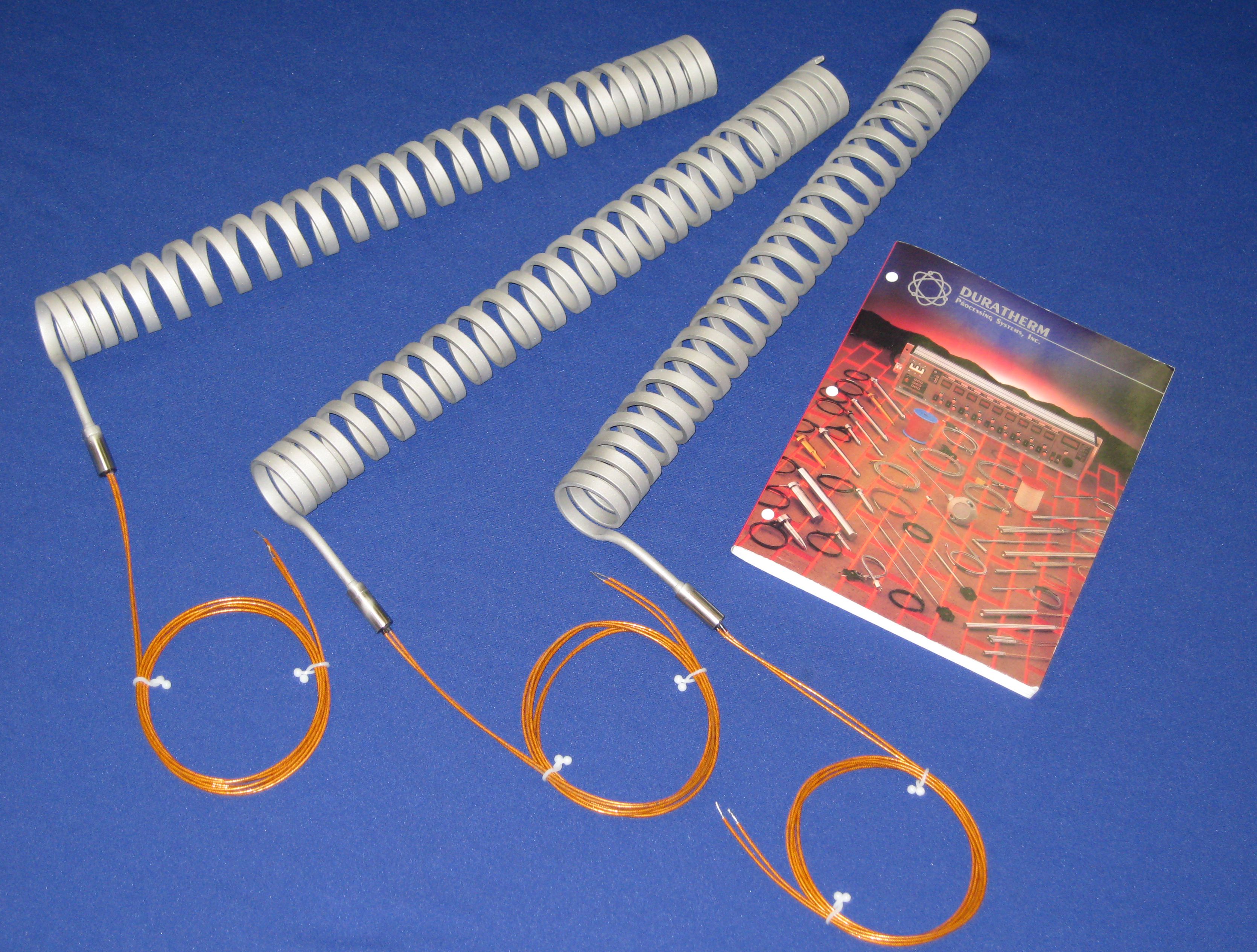

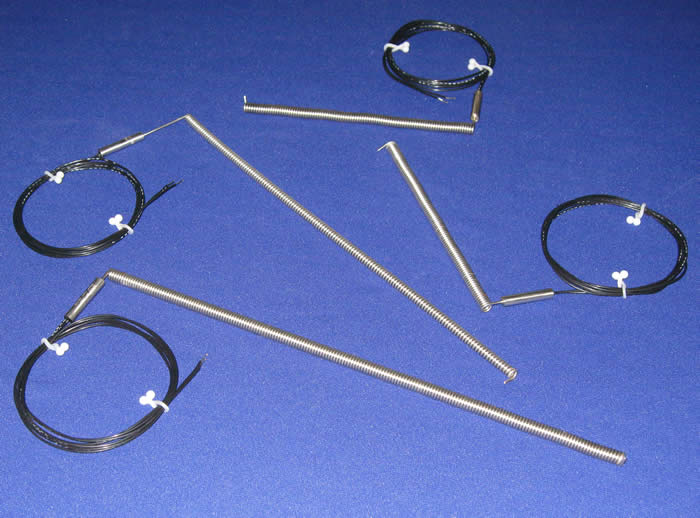

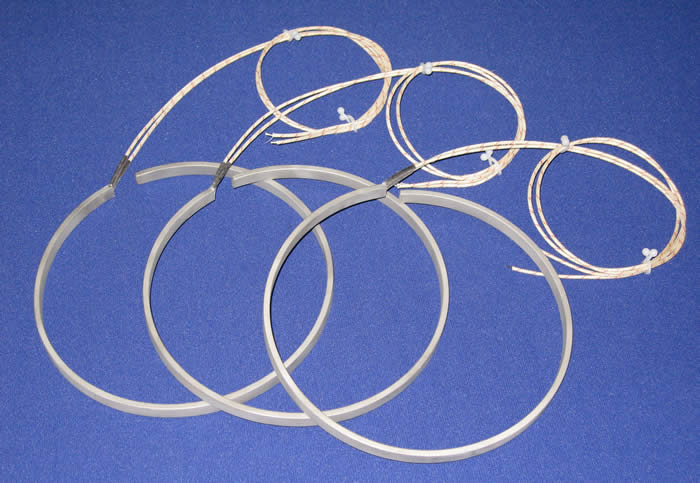

“MAXPAK” high performance cable heaters are offered in a variety of round, square and rectangular cross sectional constructions. Standard configurations include precision coiled or formed configurations as well as straight styles intended for customer forming. Straight “MAXPAK” cable heaters are fully annealed and are designed to satisfy customer in-house forming and coiling requirements as well as providing a range of stock elements for expedited delivery. Formed “MAXPAK” cable heaters are factory formed to customer specifications. Precision coiled “MAXPAK” cable configurations are available in both stock configurations and custom coiled to customer specifications.

“MAXPAK” cable heaters feature precision wound parallel coil elements fusion welded to nickel cold pins. The element assemblies are embedded within high purity ceramic and encased in an oxidation resistant metal sheath. The cable heaters are swaged to the final rectangular, square or round cross-sectional dimensions to compact the internal ceramic core and ceramic insulation to near theoretical density. This high density construction maximizes heat transfer and dielectric properties and provides the high level of reliability and performance required for even the most demanding of applications.

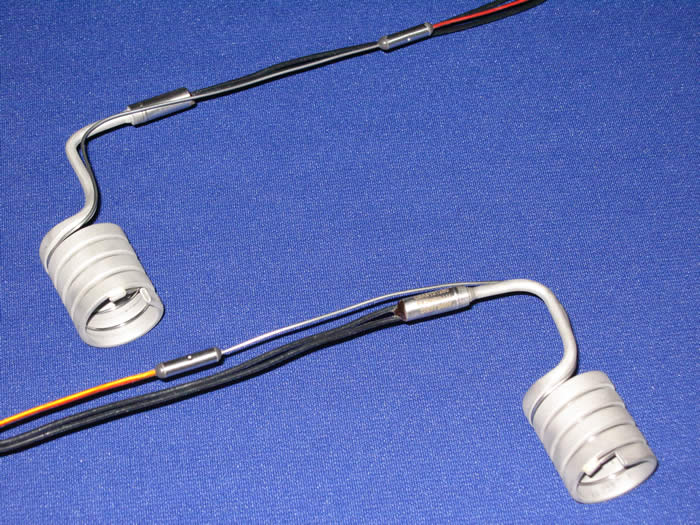

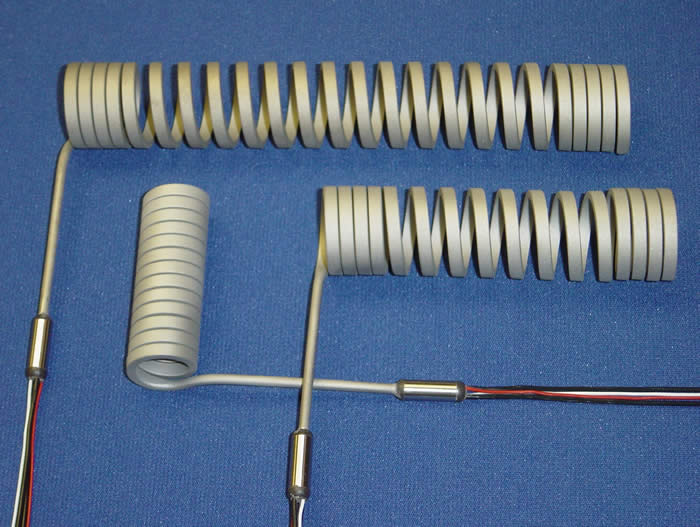

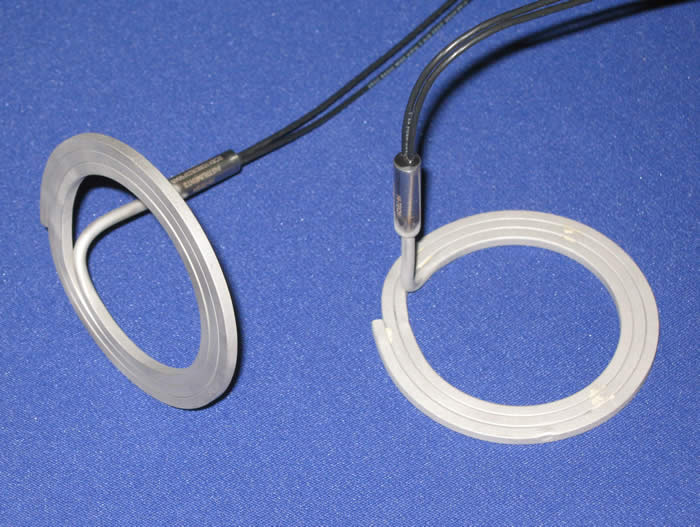

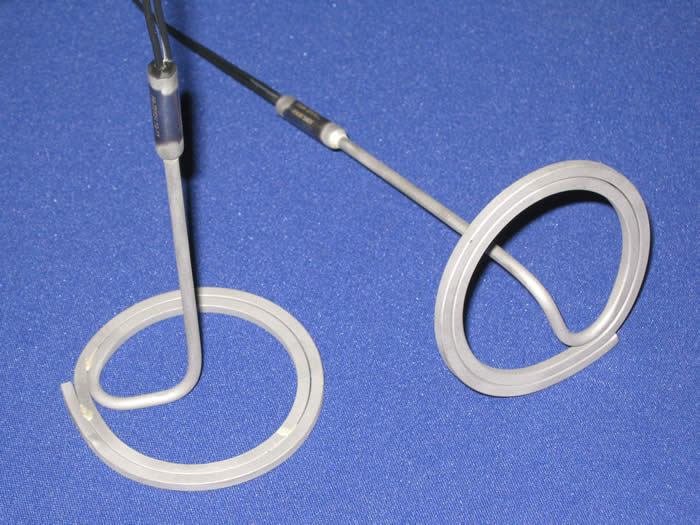

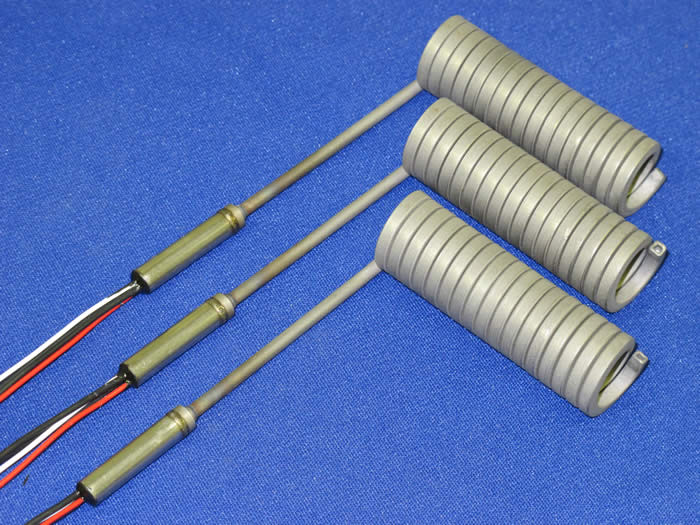

High performance coiled coiled cable configurations are engineered for cylindrical heating applications requiring any combination of high temperature, maximum wattage and abuse resistance. The coiled heaters inner and outer diameters provide a large surface area and precision fit to external or internal cylindrical surfaces. The resulting high rate of heat transfer to the component maximizes element life and efficiency. Metal sheathed construction combined with rugged lead terminations provide superior durability. Common plastic processing applications include heated bushings and nozzles for runnerless tooling, sprue bushings and molding machine nozzles.

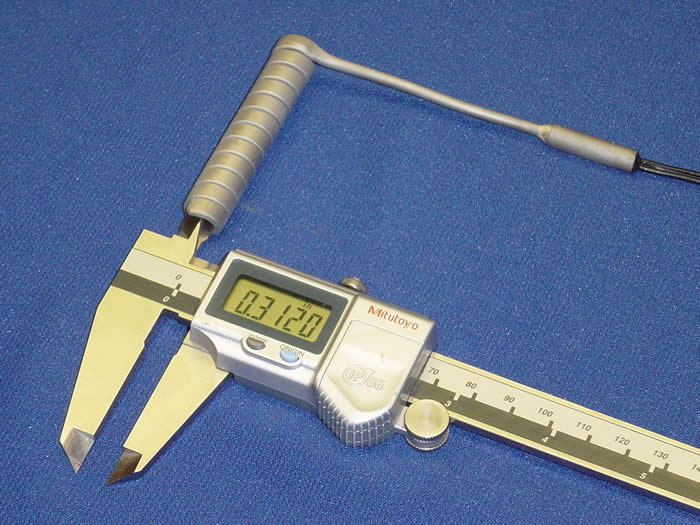

Coiled cable configurations are precision formed utilizing computerized numerically controlled coiling machines for optimum uniformity and precision. For even greater precision and performance, the coiled cables can be sized to closer tolerances by means of a secondary compaction process. This process permits inside diameter tolerances to be held to within plus or minus .0005 inches and outside diameter tolerances to within plus or minus .001 inches.

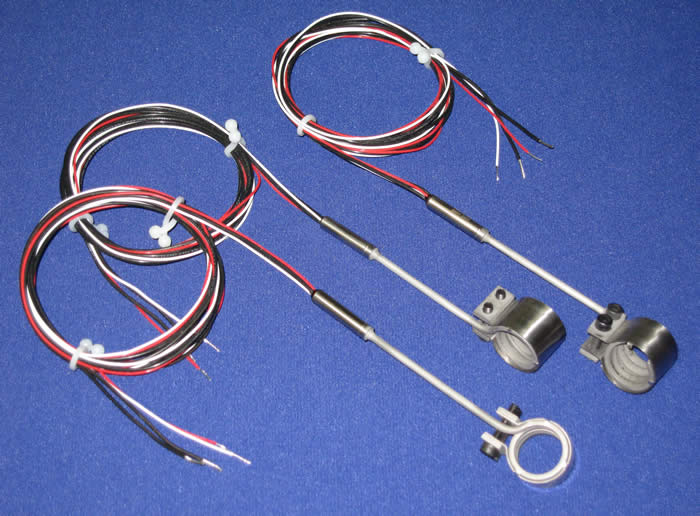

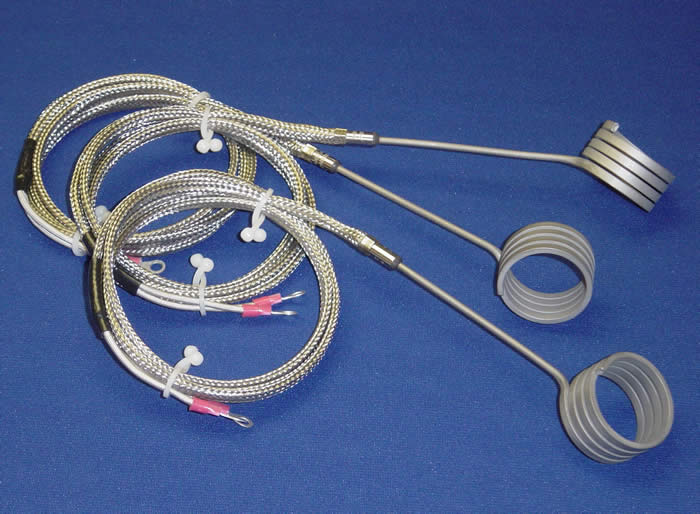

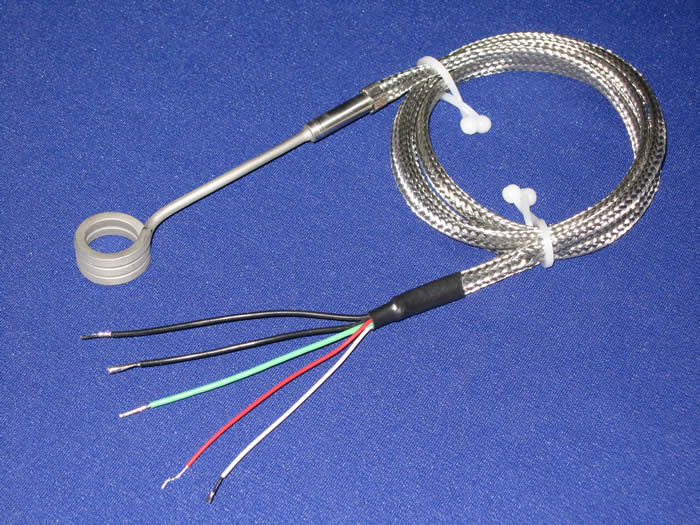

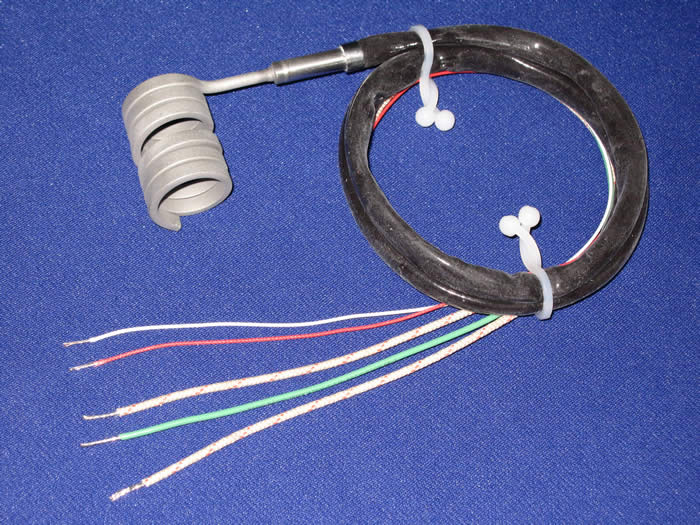

Special cable heater design features including cold sections, distributed wattage and internal temperature sensors can be implemented when required. “MAXPAK” cable heaters can also be equipped with a variety of special mounting fittings. Common mounting features include tabs, flanges, NPT screw plug, bulkhead and compression fittings. Lead terminations options include the standard round cold extension with transition and leads with a full selection of sleeve, wire braid and armor lead protection. A variety of custom lead terminations are also available for applications with special termination requirements.

- High Performance Swaged Construction. Compacted high performance swaged cable heater design maximizes heat transfer for optimum heater performance and element life.

- Premium Electrical Properties. High purity ceramic insulation materials in combination with proprietary post processing operations maximizes insulation resistance and dielectric properties. All Duratherm cable heaters feature improved high voltage stability and reduced ground current leakage values.

- Superior Internal Element Coverage. Cable element coil is designed for maximum element wire size and surface coverage to increase wattage capabilities and reduce wire loading.

- High Quality Micro Welded Internal Connections. Cable element to conductor pin connection are fusion welded for maximum connection reliability.

- Durable Heavy Duty Sheath. “MAXPAK” cable heaters feature a rugged, oxidation resistant sheath. Available sheath materials include various stainless steel and incoloy compositions.

- Versatile Configurations And Cross Sections. “MAXPAK” cable heaters are supplied in straight, formed and coiled configurations. Standard styles include round, square and rectangular cross sections.

- Precision Coiled Styles. “MAXPAK” coiled cable heaters are formed on computer controlled coiling equipment for for optimum precision and repeatability in both single zone space wound and multiple zone distributed wattage configurations.

- Transition Style Lead Terminations. Standard leads exit from a durable hermetically sealed transition providing a reinforced and moisture proof lead system. Optional lead insulation materials and lead protection provide trouble free operation.

- Fast Delivery Of Standards And Specials. Computerized design system and a streamlined production process assures fast delivery of both standard and custom cable heaters in straight, formed and coiled configurations.