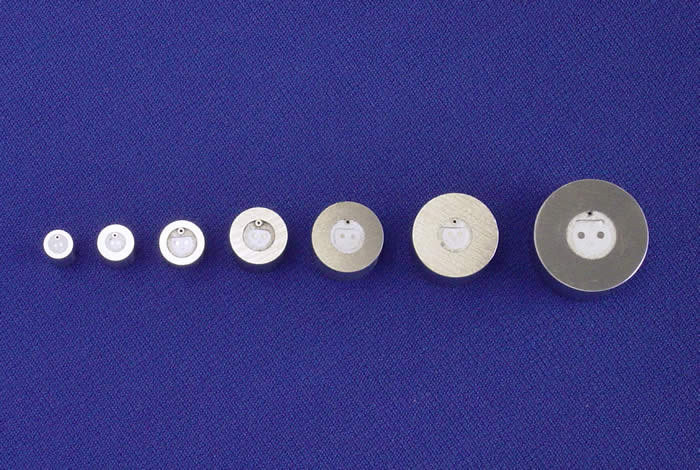

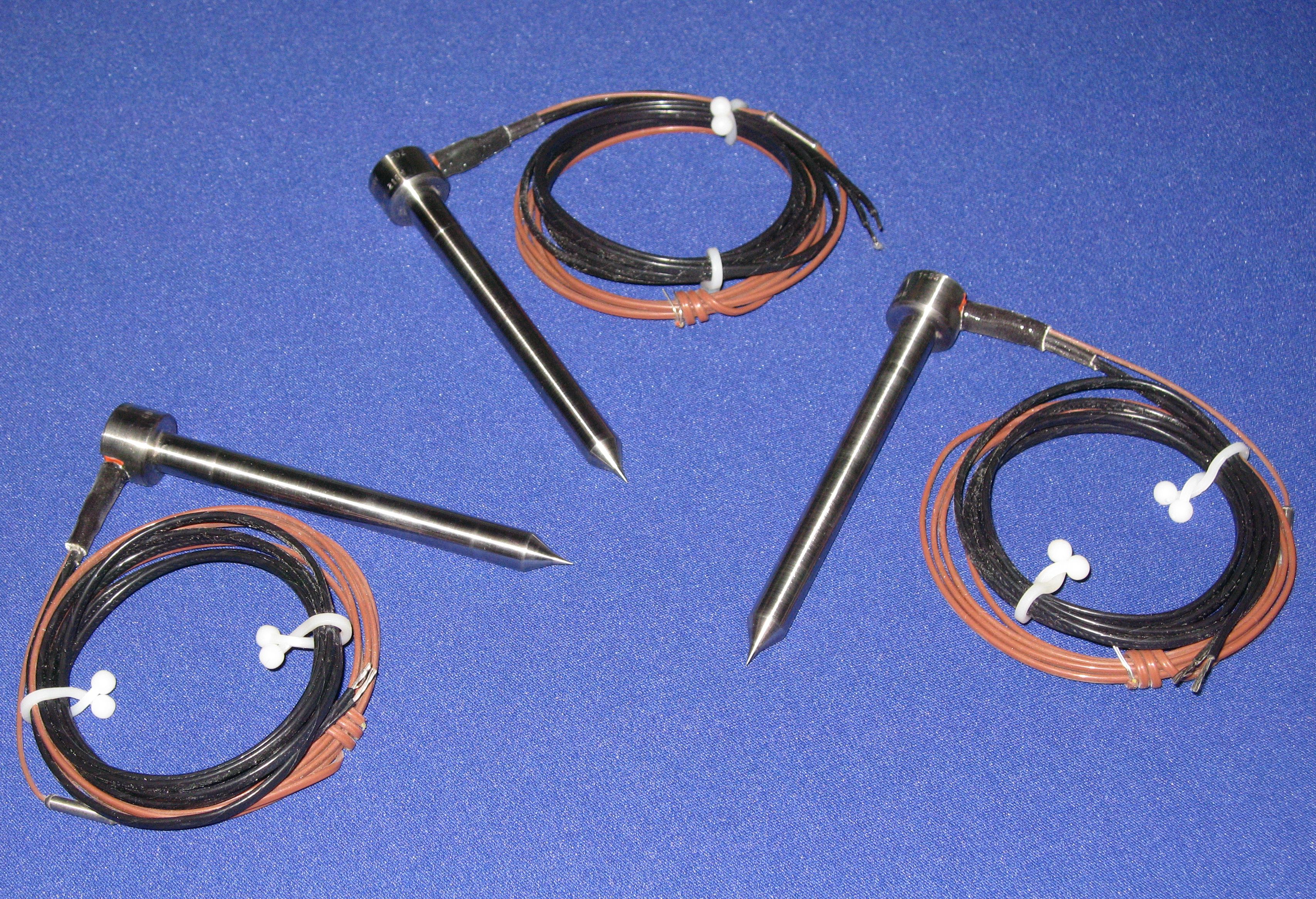

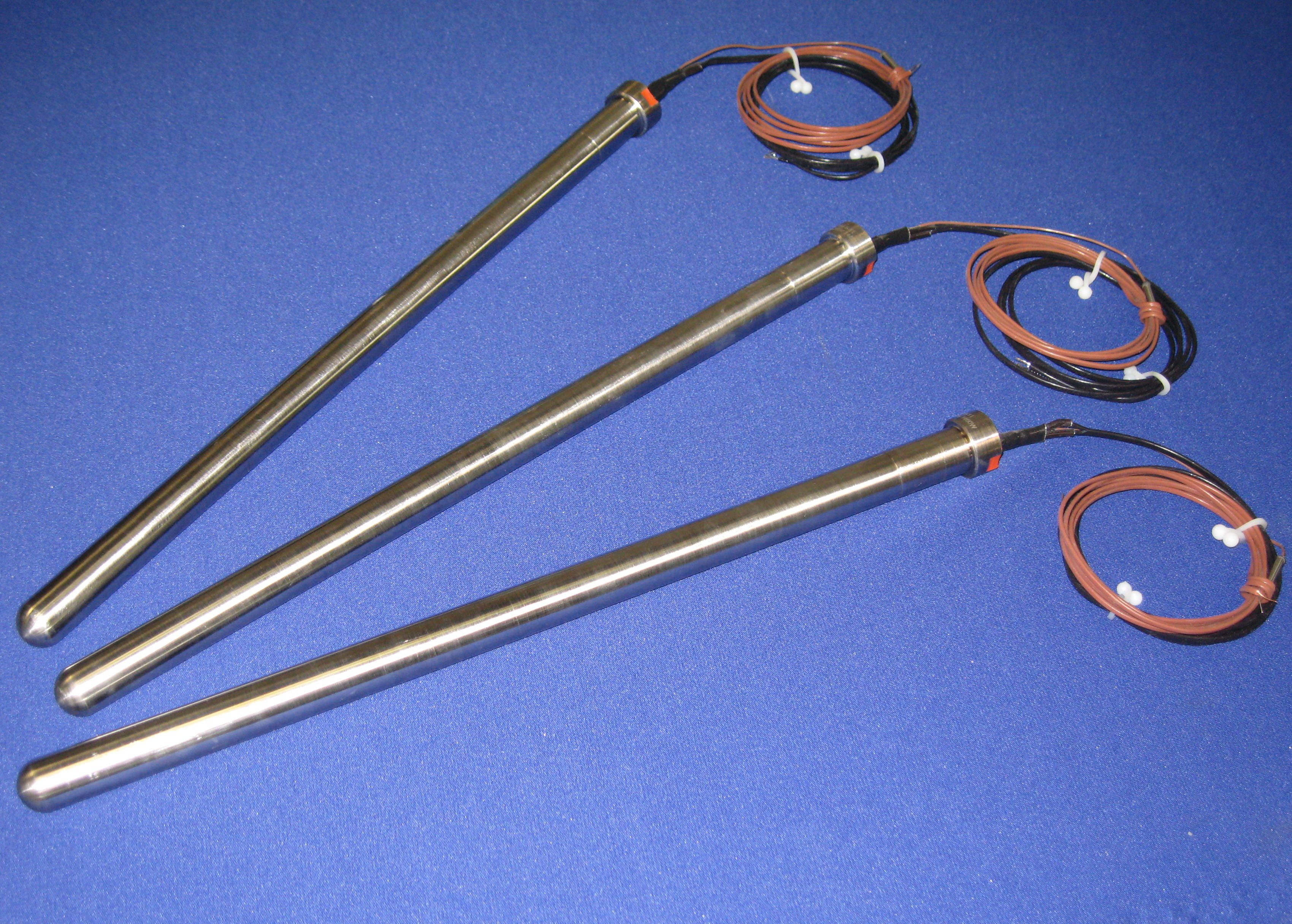

Side-Feed Torpedoes In Assorted Sizes, Styles & Dimensional Configurations

Our impressive “SOLUTION” torpedo construction has established a level of durability, performance and versatility surpassing all others in the industry. This integral heated construction results in an incredibly reliable torpedo capable of peak performance under the most severe operating conditions.

“SOLUTION” torpedo thermal characteristics are coordinated to the actual mold environment. This thermal coordination establishes the optimum temperature profile for actual mold operating conditions and provides the temperature uniformity essential to quality molding of all thermoplastic resins.

A removable mineral insulated thermocouple installed into the “SOLUTION” torpedoes’ integral thermowell provides precise temperature control.

“SOLUTION” torpedo performance has been extensively evaluated in a variety of molding applications. Our years of consistently superior results have shown the “SOLUTION” torpedo to be the highest performance torpedo ever manufactured. Our system coordinated heat profiles have made the “SOLUTION” torpedo the logical choice for processing both commodity and engineering resins.

Standard “SOLUTION” torpedo components are offered in a variety of configurations and sizes designed to accommodate most common runnerless molds utilizing gating torpedoes, runner torpedoes or distribution bar components.

Custom “SOLUTION” torpedo components are readily available and can be supplied in configurations designed to satisfy special dimensional requirements in new molds or to retrofit existing components in problem molds.