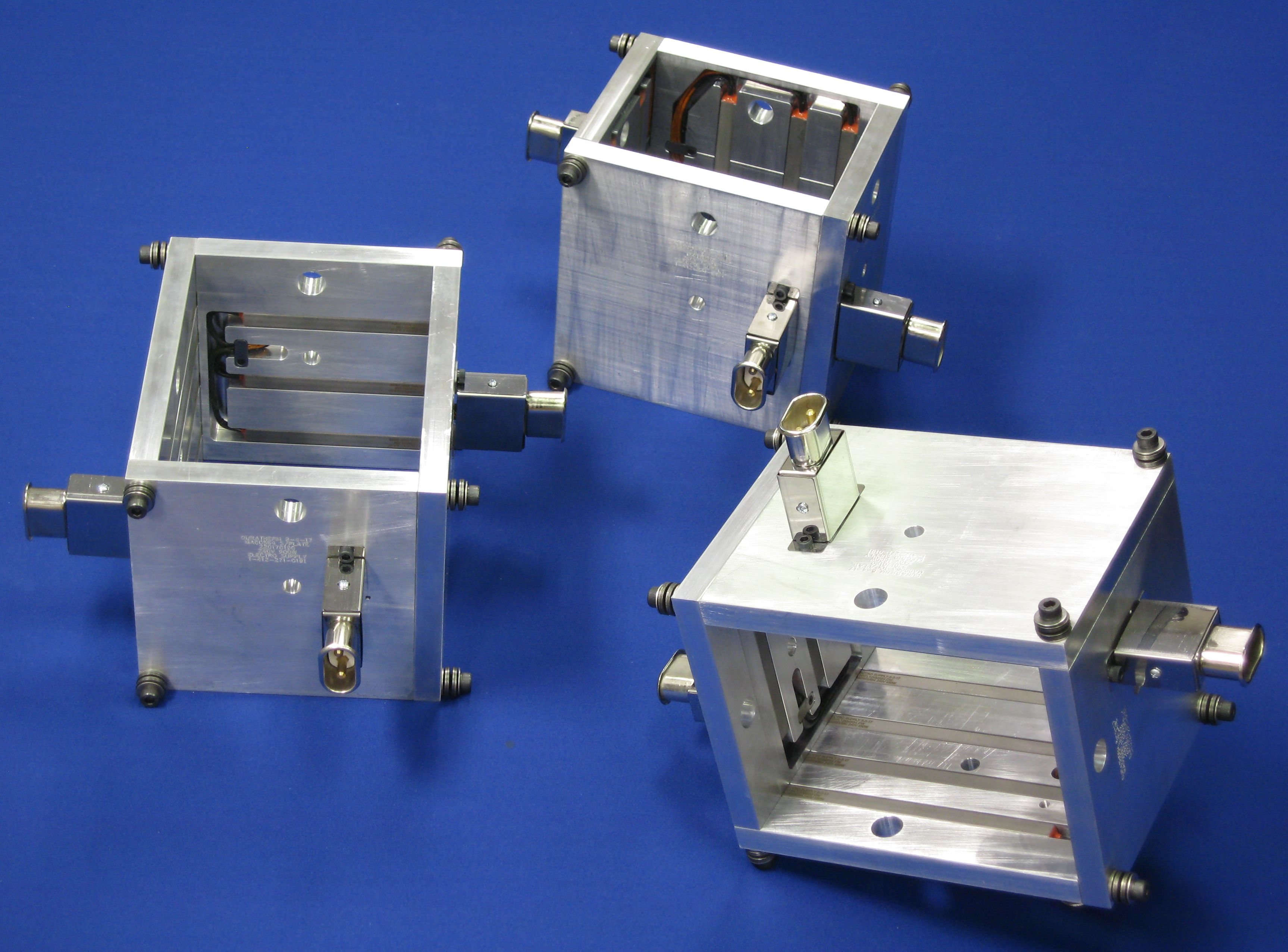

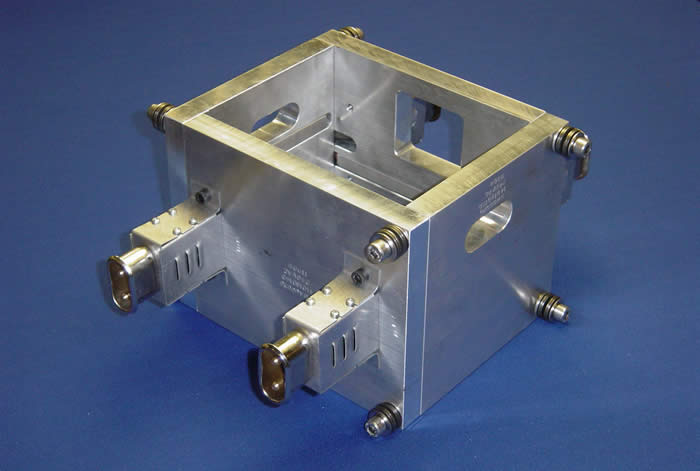

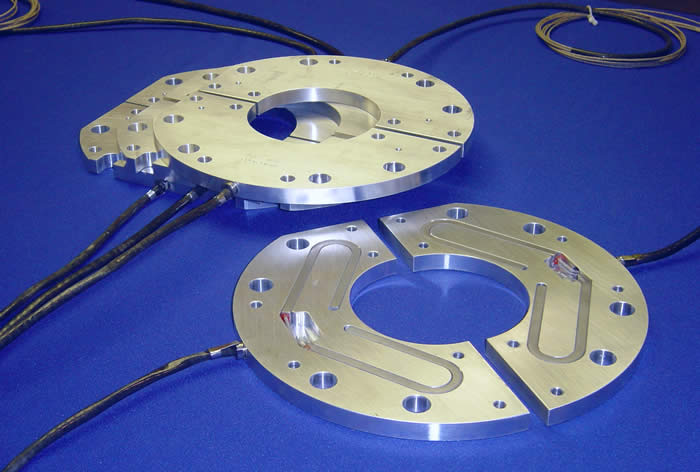

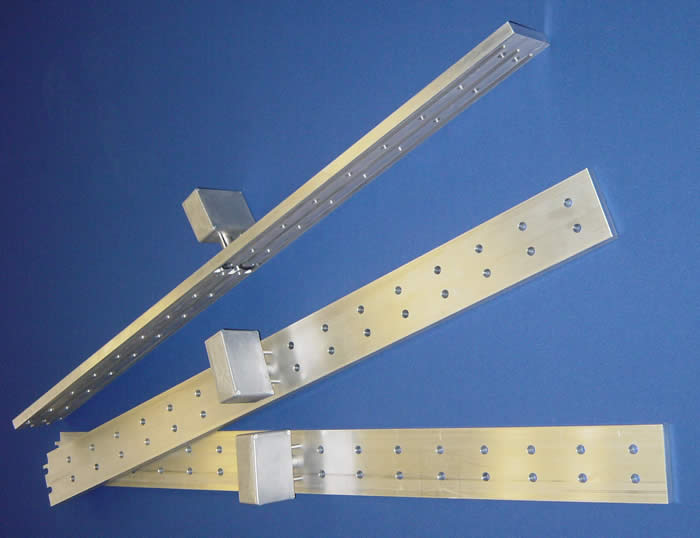

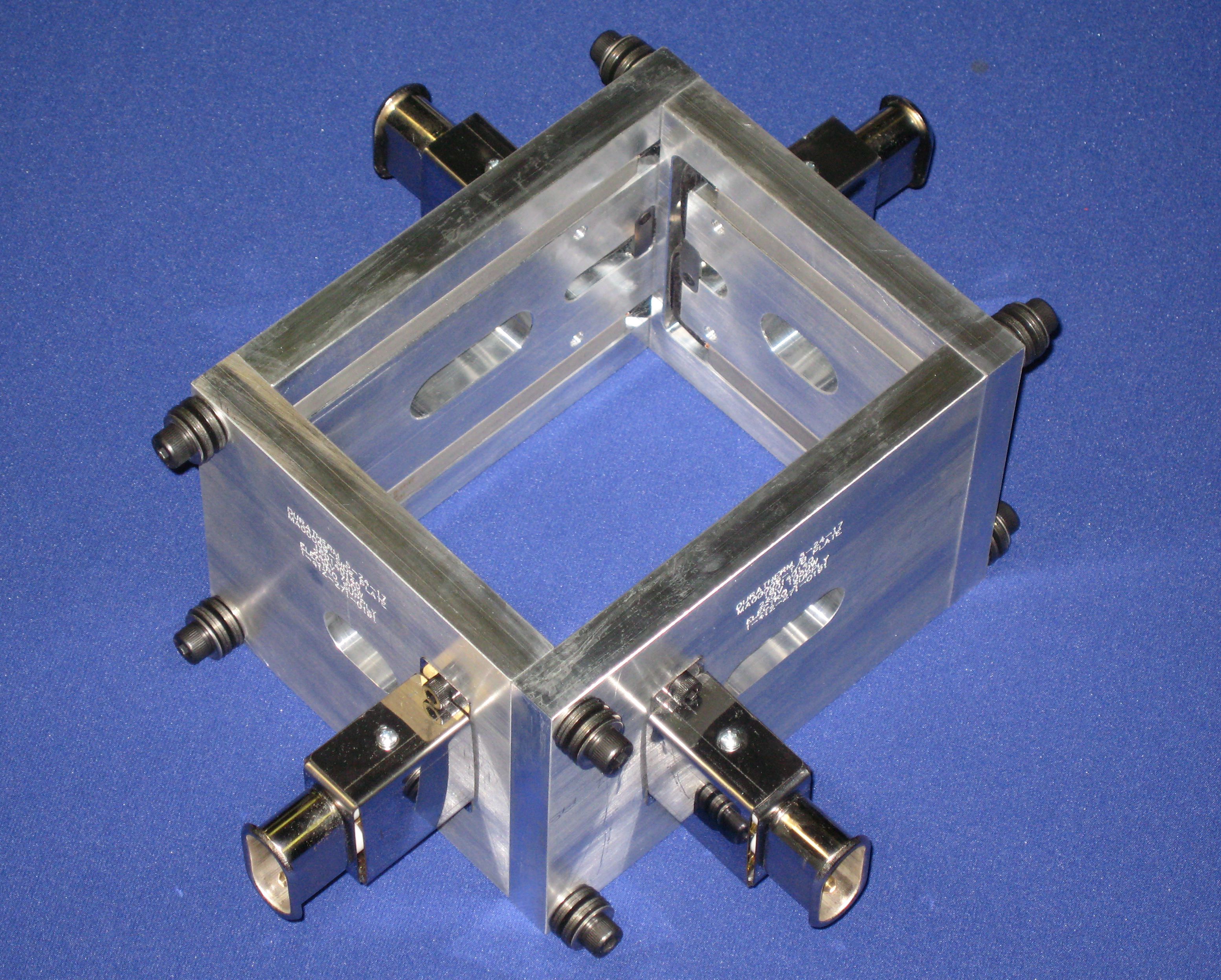

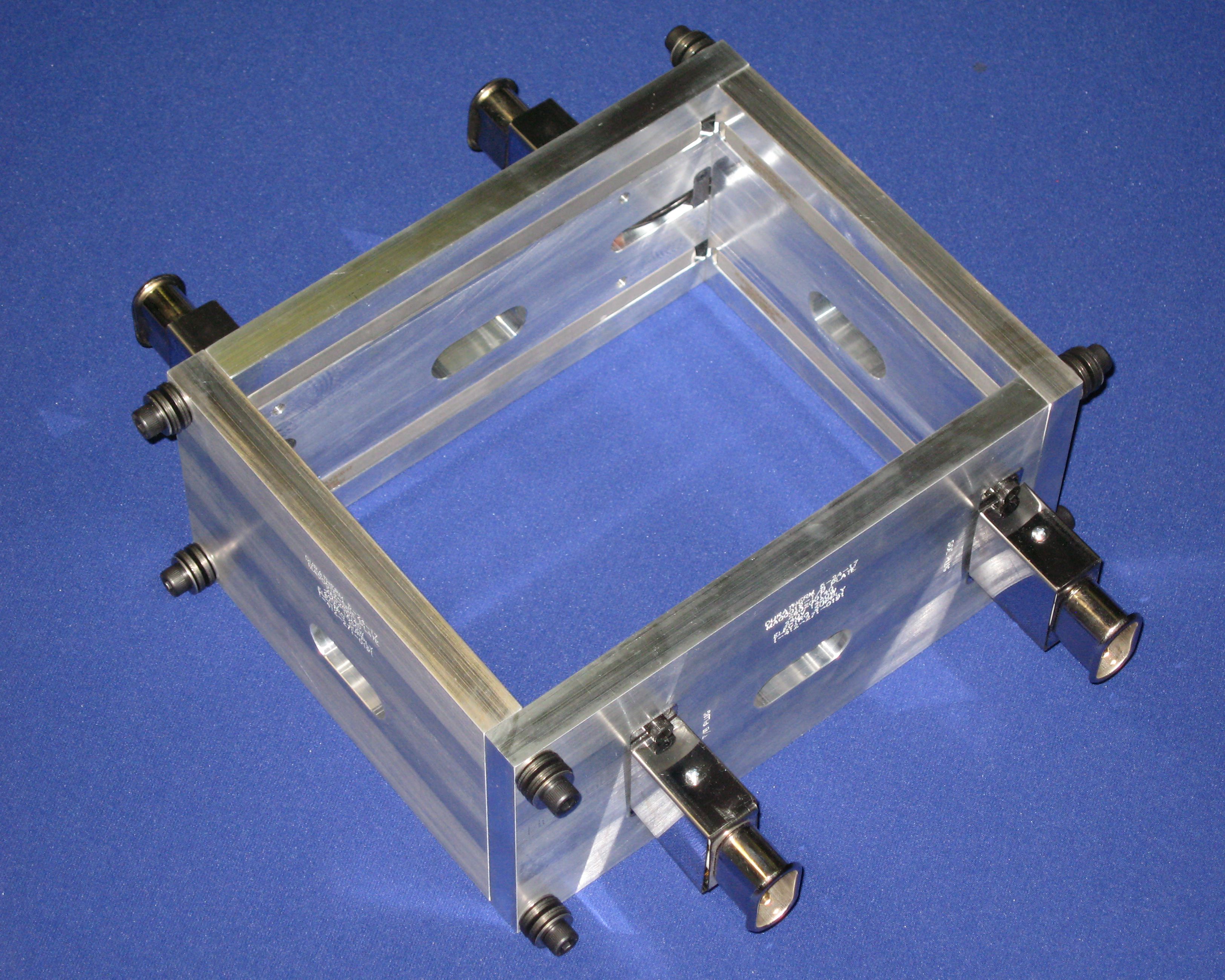

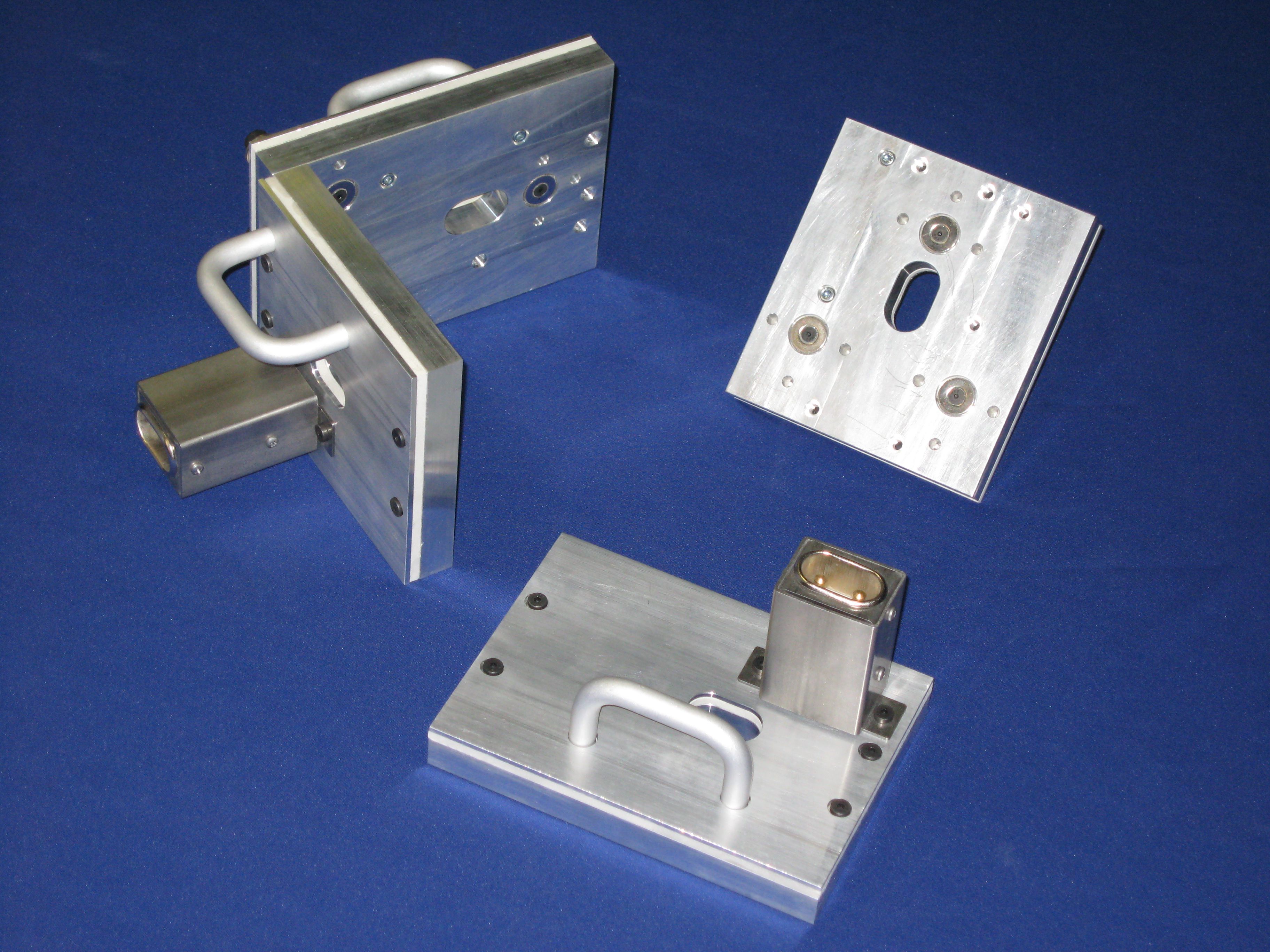

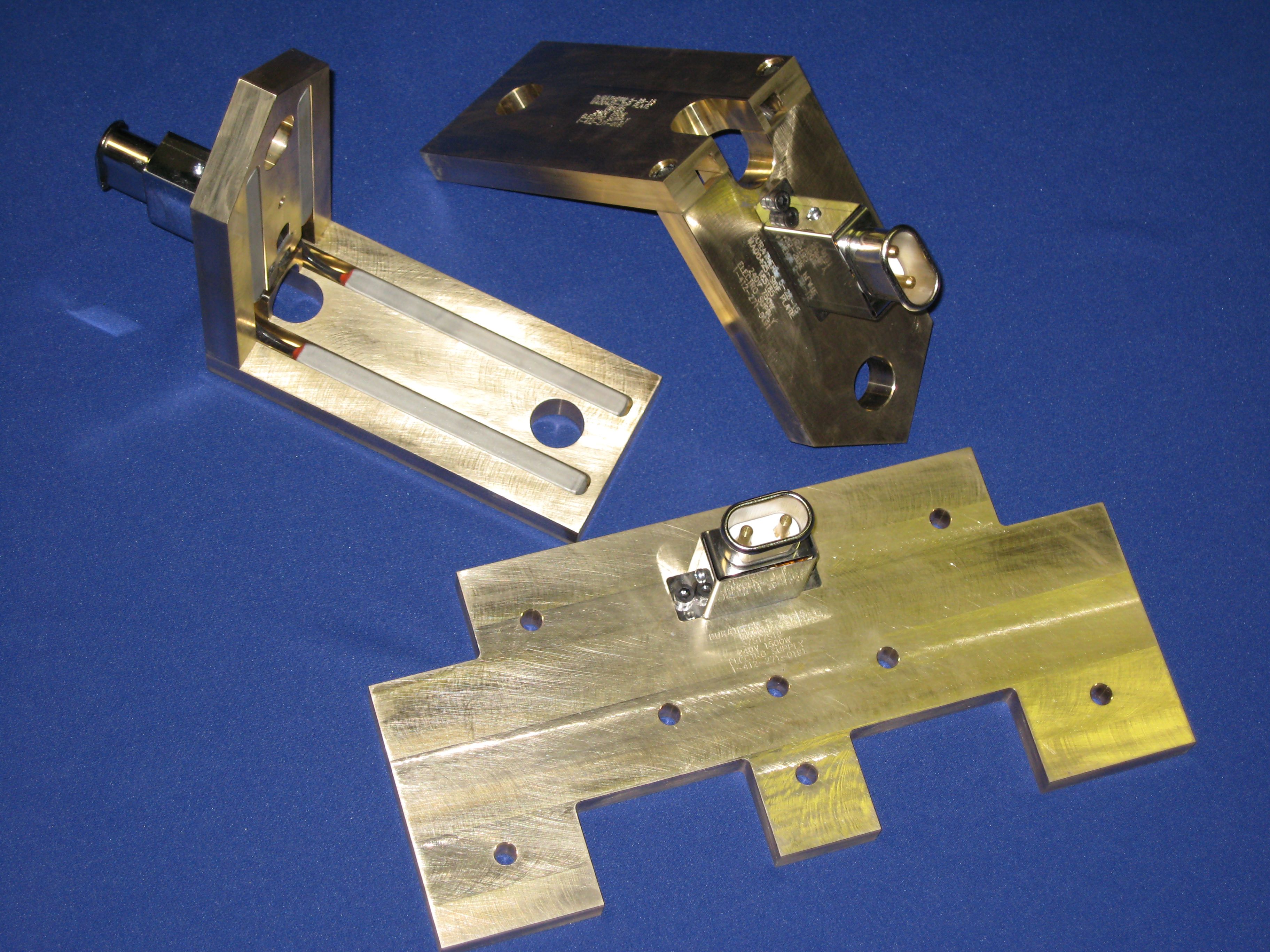

Duratherms’ new precision plate and component heater assemblies are designed for a wide range of extrusion, molding and packaging applications. The rugged, high performance assemblies are providing exceptional performance in the heating of extrusion profile dies, blow molding manifolds and die heads, wire cross head dies, extruder barrels and injection molds.

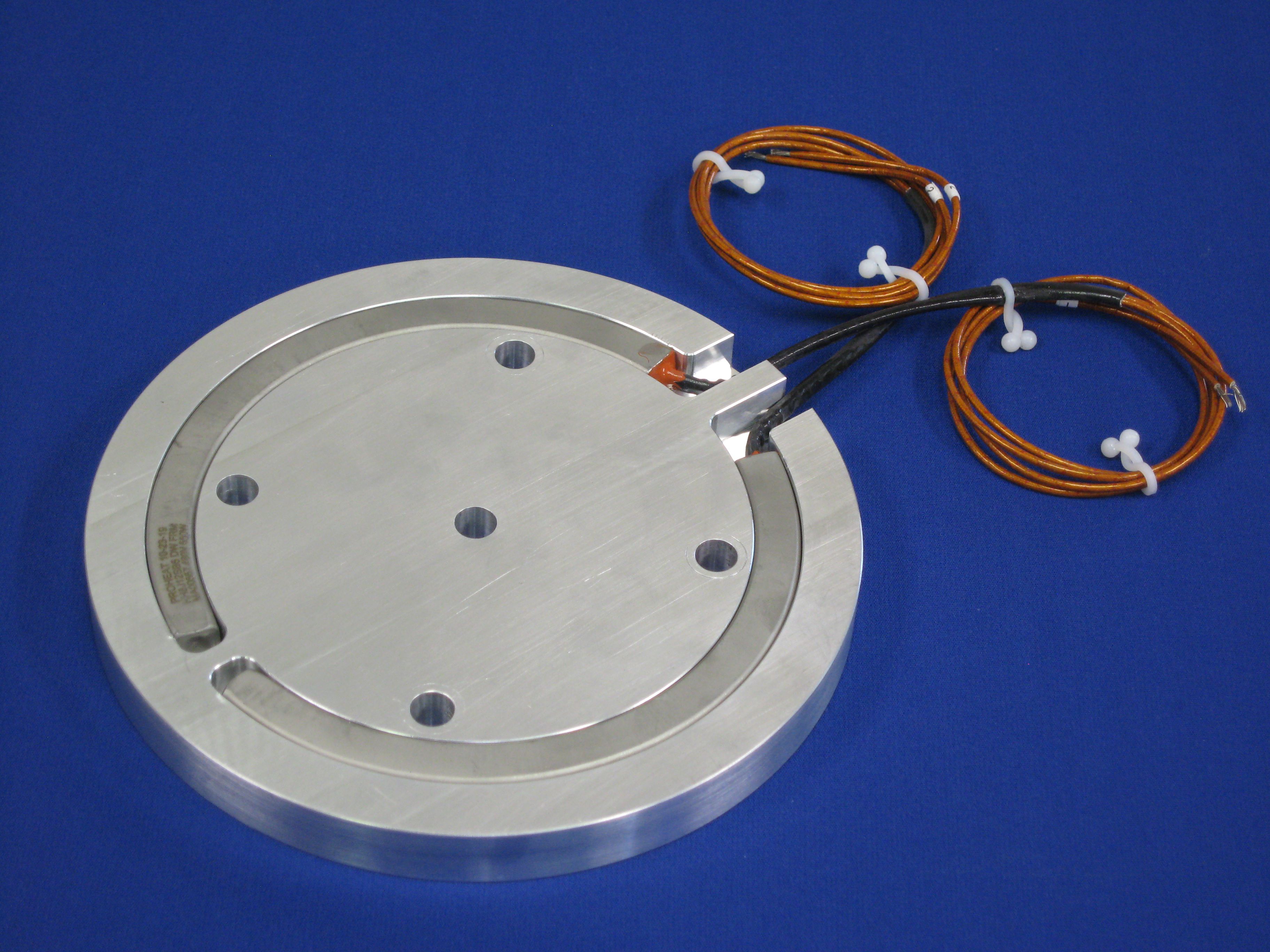

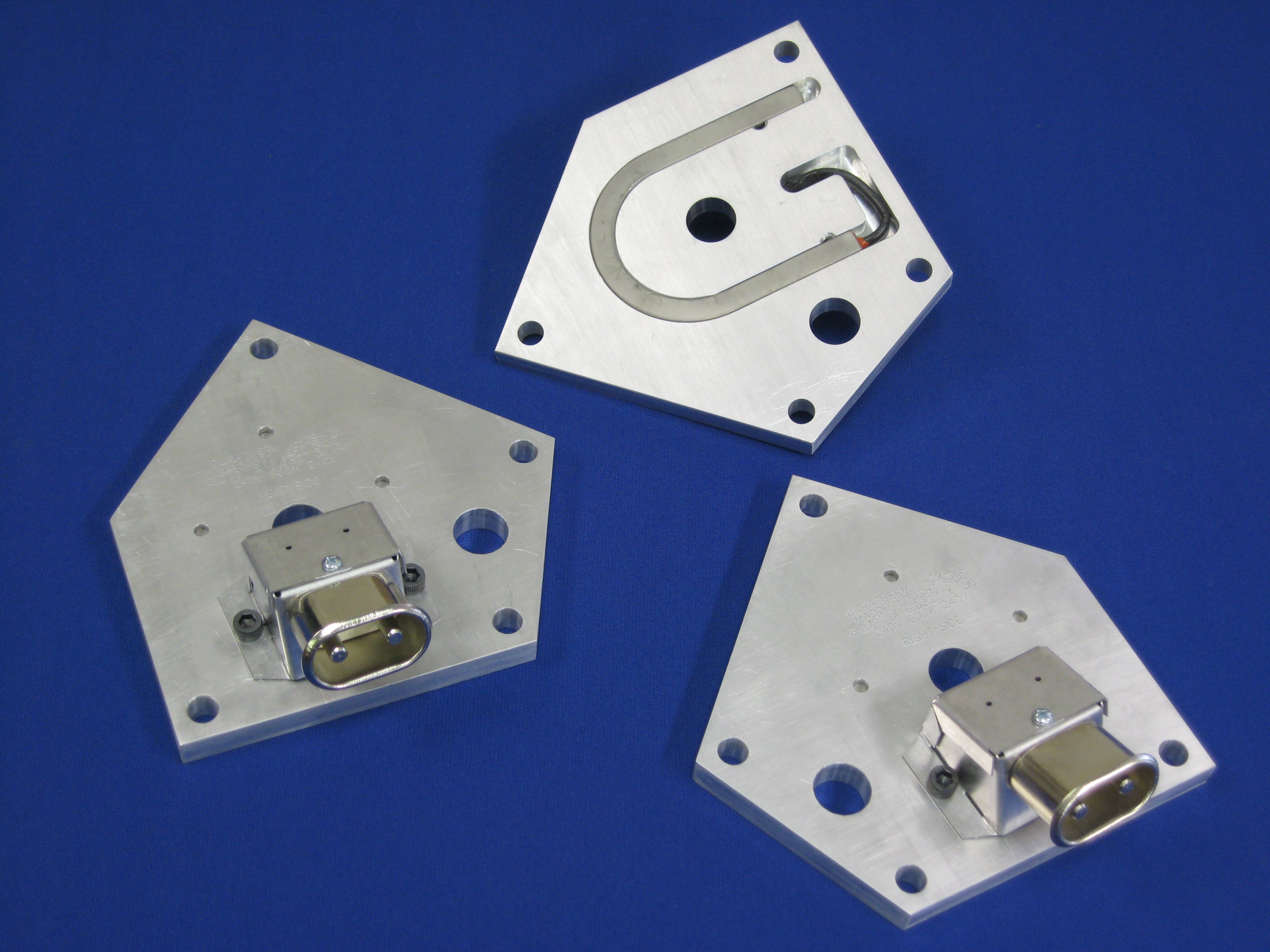

The plate heater assemblies consist of machined plates which accommodate either “MAXPAK” square swaged cartridge heater (U.S. and foreign patents pending) or formed cable heaters. The heater assemblies can be supplied in any desired material including aluminum, bronze, stainless steel and steel. The plates and components can be readily plated or coated to provide corrosion resistance or special non-stick properties for sealing applications. A slot style square cartridge or cable heater and lead mounting method insure full protection of the elements and lead system while simplifying repair of accidental damage.

The new plate and component heater design provides higher reliability and performance than cast and mica style plate heaters while offering greater versatility. The assemblies do not require patterns for temporary sand molds or expensive permanent molds and can be manufactured in smaller sizes, thinner constructions and more complex configurations than cast heater or mica plate heater styles. Performance benefits include higher temperature and wattage capabilities, improved heat uniformity, reduced thermal mass and increased heating efficiency. Plate and component heater assemblies having irregular shapes and requiring multiple holes, slots and cutout areas are readily manufactured through the use of formed square cartridges installed in corresponding machined mounting slots. Special features including distributed wattage, multiple independent heat zones and internal temperature sensors are easily added.

Duratherm’s precision plate and component assemblies improve heating efficiency, allows lead and heater repair, and reduces turnaround time. The simple machined approach allows economical manufacturing of both single custom item orders and large volume orders. Companies desiring to produce their own plate or component heater assemblies can contact the factory for design assistance and purchase only the square and rectangular cartridge or cable heaters required.

Duratherm is manufacturing the plate and component heater assemblies any desired combination of material, size and configuration. The assemblies are available in typical thicknesses of 3/8, 1/2″ and 3/4″ and can be produced in thinner or thicker sections as dictated by application requirements. The assemblies are normally equipped with Duratherm’s “MAXPAK” square or rectangular cartridge heaters. Smaller plate assemblies can also be manufactured to accept cable heaters when required. A variety of lead options including plugs, electrical boxes, terminals and flexible leads are available. An assortment of sleeve, wire braid, armor and tubing style lead protection systems can also be readily implemented.