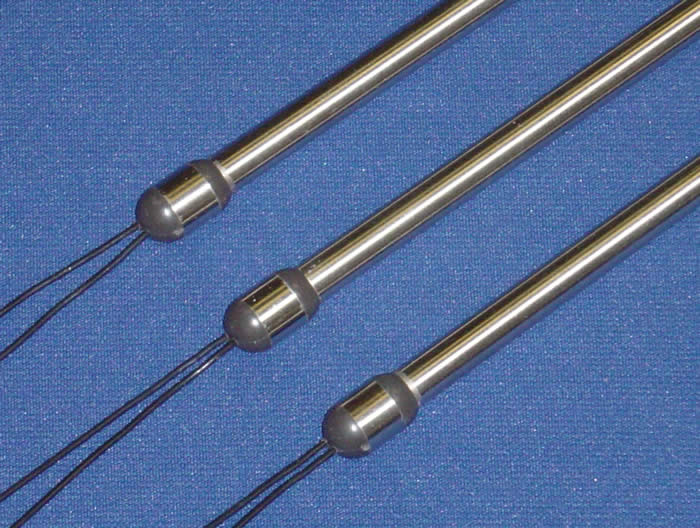

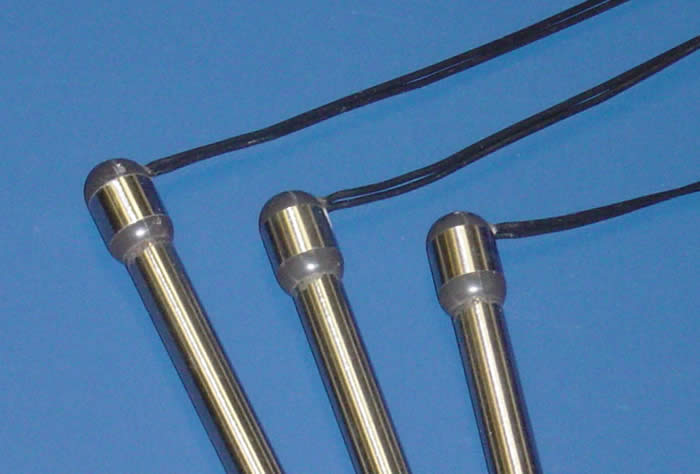

Duratherm has developed a series of standard cartridge heater configurations featuring the new high performance, sleeve molded lead exit. These lead exits can be configured as a standard molded style or as a molded style with integral metal sleeve to provide the durability and heat resistance required. High temperature thermoset resin fully encapsulates the critical cartridge lead connection area. This lead exit construction provides excellent mechanical protection and dramatically improves moisture resistance. The seal protects the element from contamination during operation and reduces moisture absorption during storage.

These high temperature metal sleeved molded transitions are available with resin rated at 800° F. (427° C.) continuous and can be supplied molded with a 900° F. (482° C.) rated thermoset material or with 600° F. (315° C.) Silicone thermoset when required.

These molded transitions offer premium performance in a low cost approach to cartridge heater lead termination.

Features of the new molded transition include the following:

1. Lower cost – Molding operation eliminates many manual operations required for potted style transitions.

2. Superior seal – Total encapsulation of cartridge to lead connection provides excellent resistance to moisture. The seal protects the element from contamination during operation and eliminates moisture absorption during storage.

3. Heat resistant – Standard resin materials offer continuous operating temperatures of 600°, 800° and 900° F.

4. High strength – Molded transition with the integral metal sleeve is extremely resistant to breakage, provides high pull strengths and is well suited for many cartridge heater applications.

5. Versatile – Molded cartridge heater transitions provide a rugged, high performance lead exit system. Our in-house tooling and molding capabilities allows us to offer custom termination systems when required.