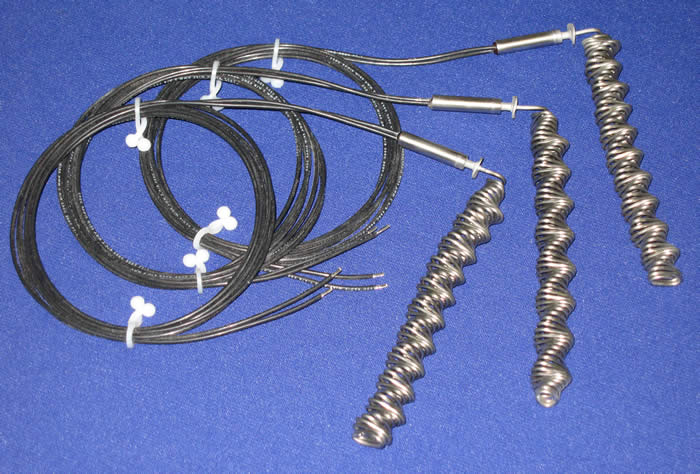

“MAXPAK” Mini Flex Cable Air Heaters satisfy the need for an easily formable cartridge heater. These heater can be readily installed in tooling where the heat source must be mounted in a shaped configuration. Precision coiled cable configurations are available in both stock configurations and custom coiled to customer specifications.

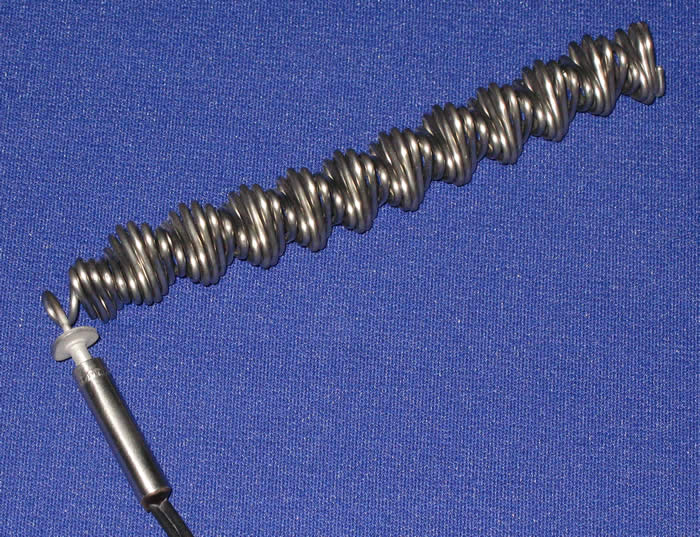

“MAXPAK” Mini Flex Cable Air Heaters feature precision wound drawn cable elements connected to leads within a transition lead fitting. The mini flex cable coils are then factory coiled to customer specifications. The cable element consists of nickel chromium wire assembled into high purity ceramic and encased in an oxidation resistant inconel metal sheath. The cable assembly is then drawn to to compact the internal ceramic core and ceramic insulation to near theoretical density and to achieve the desired final diameter and resistance. The drawn compacted construction maximizes heat transfer and dielectric properties and provides the high level of reliability and performance required for even the most demanding of applications.

All Duratherm “MAXPAK” Mini Flex Cable Coils feature a hermetically sealed transition for total protection from moisture and contamination.. This transition design features a true high temperature, glass sealed transition construction which eliminates absorption of dielectric reducing moisture and other contaminanants. High temperature ceramic insulation fully encapsulates the critical cable and lead connection area. The laser welded transition configuration provides a rugged, abuse resistant transition ideal for cable heaters supplied in straight lengths for customer forming. This transition is also available as an option for preformed or coiled cable heater configurations. This transition construction provide the highest level of mechanical protection and eliminates the loss of insulation propertied due to moisture absorption and contamination. The seal eliminates moisture absorption during storage and protects the element from contaminants during operation.

High performance coiled coiled cable configurations are engineered for cylindrical heating applications requiring any combination of high temperature, maximum wattage and abuse resistance. The coiled heaters inner and outer diameters provide a large surface area and precision fit to external or internal cylindrical surfaces. The resulting high rate of heat transfer to the component maximizes element life and efficiency. Metal sheathed construction combined with rugged lead terminations provide superior durability. Common plastic processing and packaging applications include container sealing heads.

“MAXPAK” Mini Flex Cable Coils are precision coiled utilizing computerized numerically controlled coiling machines for optimum uniformity and precision. Coiling options include close wound, close wound and stretched, space wound and multi-zone distributed wattage wound configurations.

“MAXPAK” Mini Flex Cable Coil can also be equipped with sleeve, wire braid and armor lead protection. A variety of custom lead terminations are also available for applications with special termination requirements.