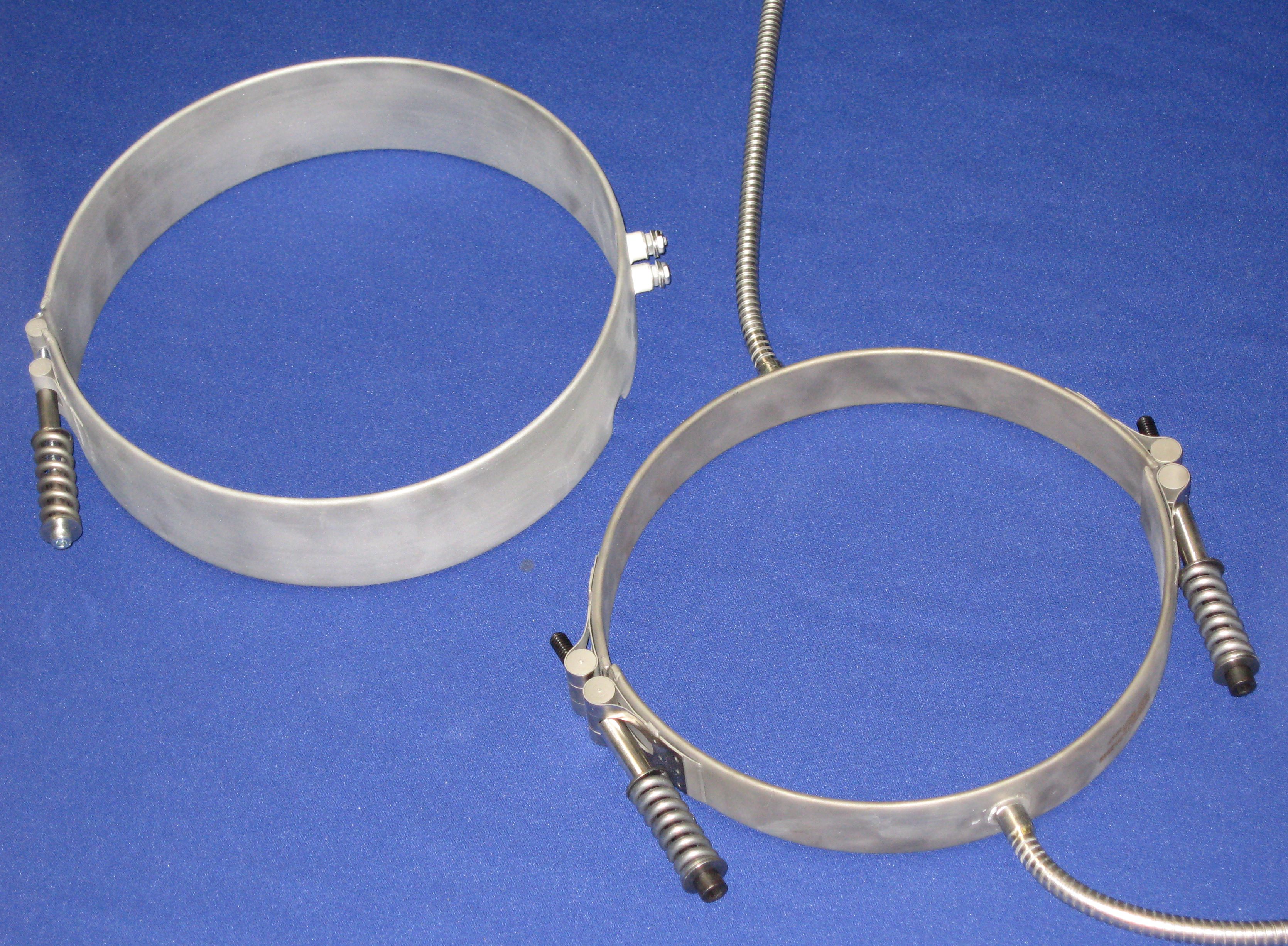

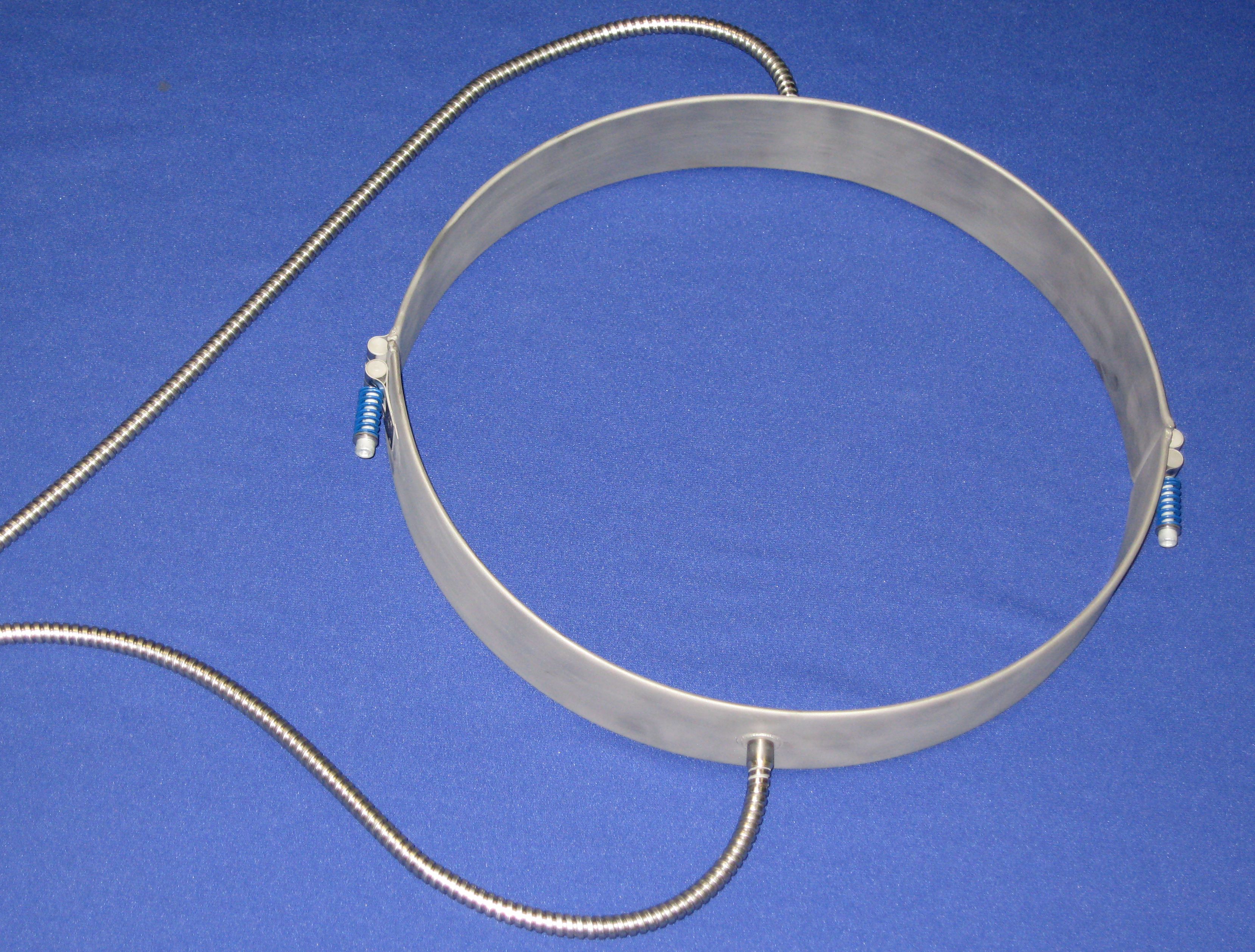

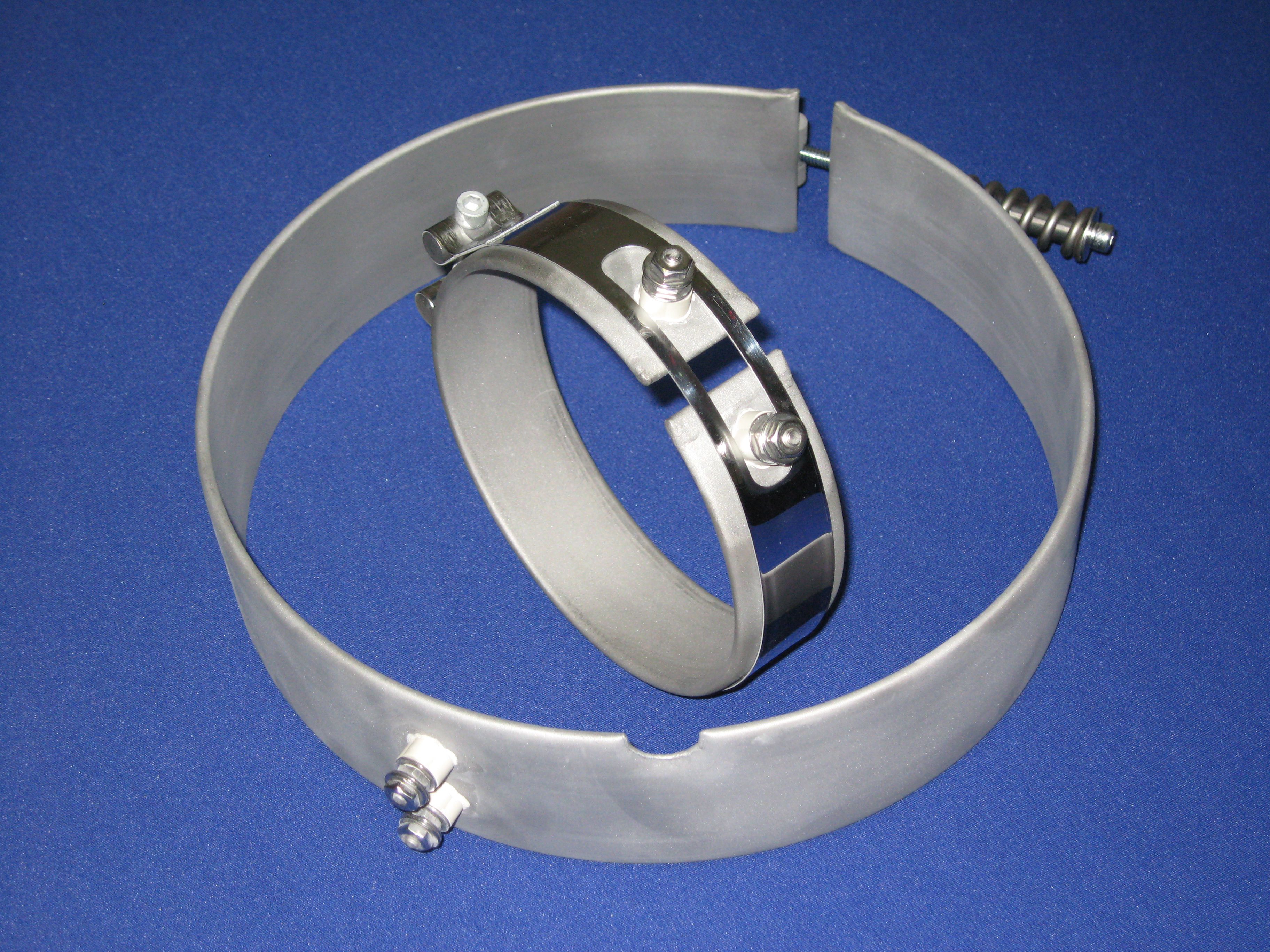

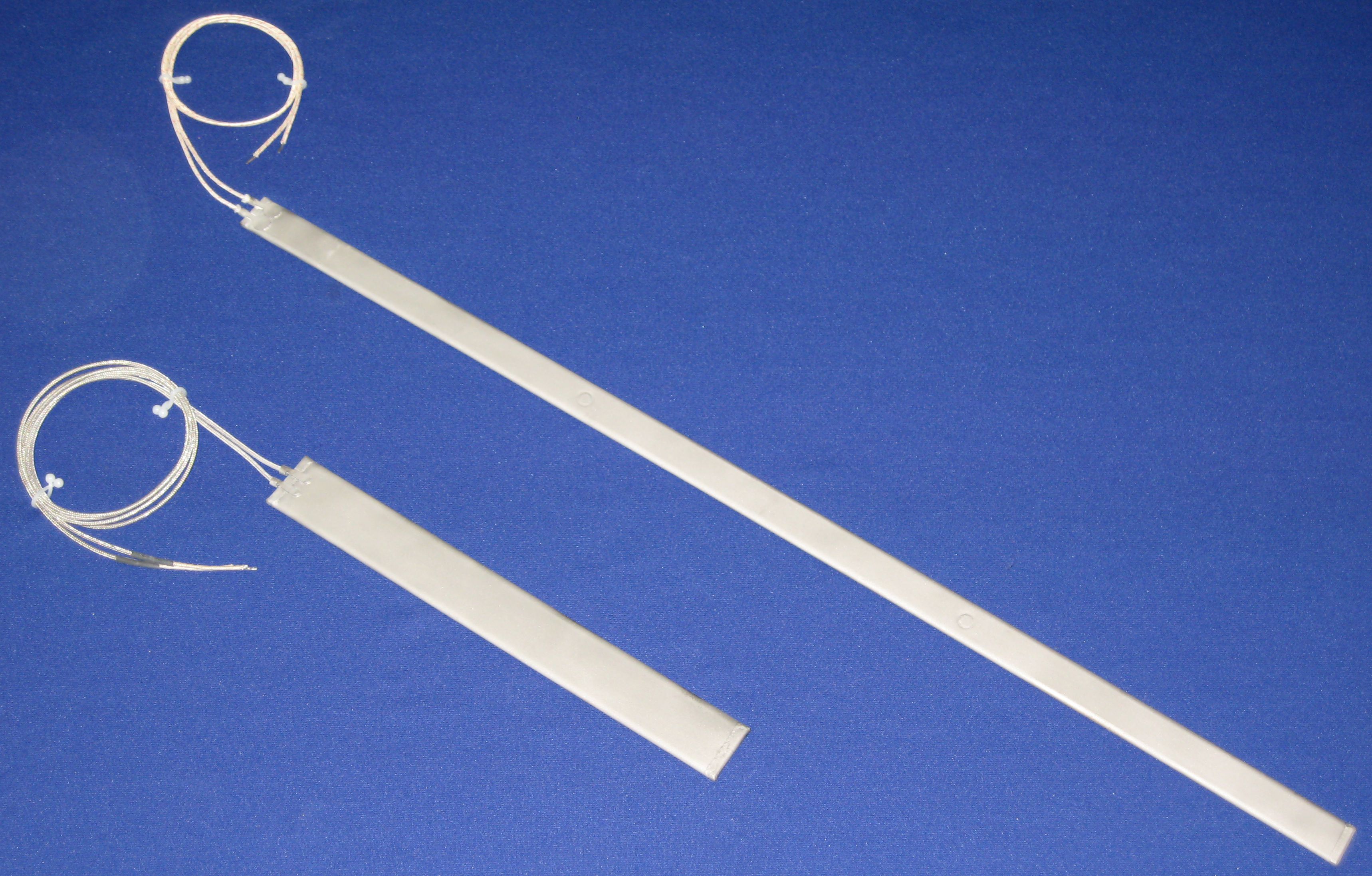

Duratherms’ new sealed, mineral insulated band and strip heaters provide the ultimate performance in high temperature, high watt density and enviornmentaly demanding applications in extrusion, molding and packaging industries. The rugged, high performance assemblies provide exceptional performance in the heating of extrusion profile dies, blow molding manifolds and die heads, wire cross head dies, extruder barrels and injection molds.

These high quality sealed band and strip heaters feature a 304 stainless steel flat tube construction weld sealed at the ends for maximum resistance to moisture, contamination and corrosion. The internal elements are totally embedded in highly compacted, high temperature ceramic insulation.

The sealed band and strip heater design provides higher reliability and performance than mica style band and strip heaters while offering greater versatility. Performance benefits include higher temperature and wattage capabilities, improved heat uniformity, reduced thermal mass and increased heating efficiency. Sealed band and strip heater assemblies requiring holes are readily manufactured.Our exclusive hole forming process expands the inner sheath into an eyelet which extends through the hole and is weld sealed at the outer sheath to maintaining the totally sealed construction. Special features including distributed wattage, multiple independent heat zones and internal temperature sensors are easily added.

Duratherm’s sealed band and strip assemblies improves performance, increases wattage capabilities and allows higher operating temperatures.

A variety of lead options including plugs, electrical boxes, terminals and flexible leads are available. An assortment of sleeve, wire braid, armor and tubing style lead protection systems can also be readily implemented.