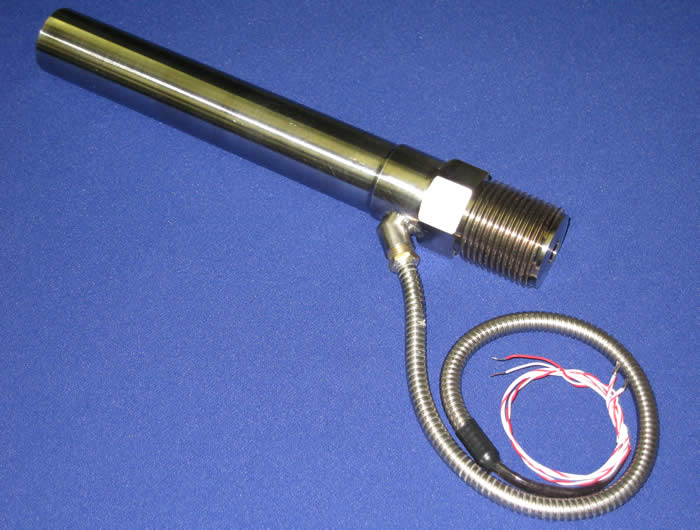

The integral heating element of the “SOLUTION” Machine Nozzle is embedded in ceramic compacted to near theoretical density for optimum heat transfer and insulation dielectric. The densely compacted assembly maximizes performance and reliability and provides total resistance to vibration, shock and physical abuse. Outstanding heat transfer from the element body substantially improves nozzle heating and cooling rates and provides superior heat uniformity and improved tip heating. These nozzles are capable of operating at temperatures up to 1600° F. continuous.

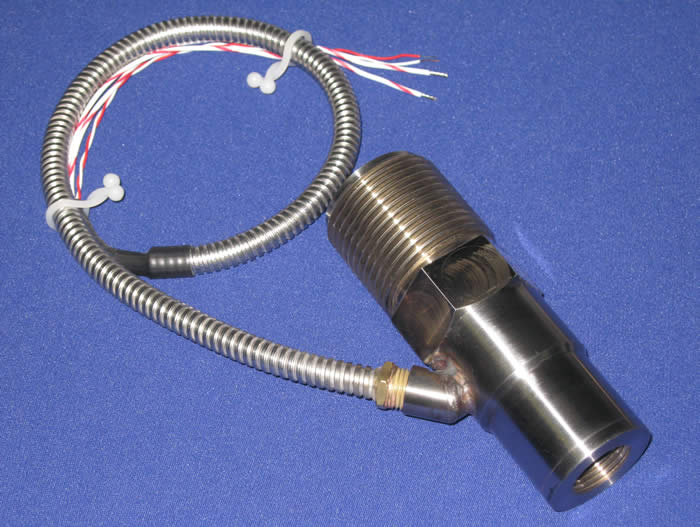

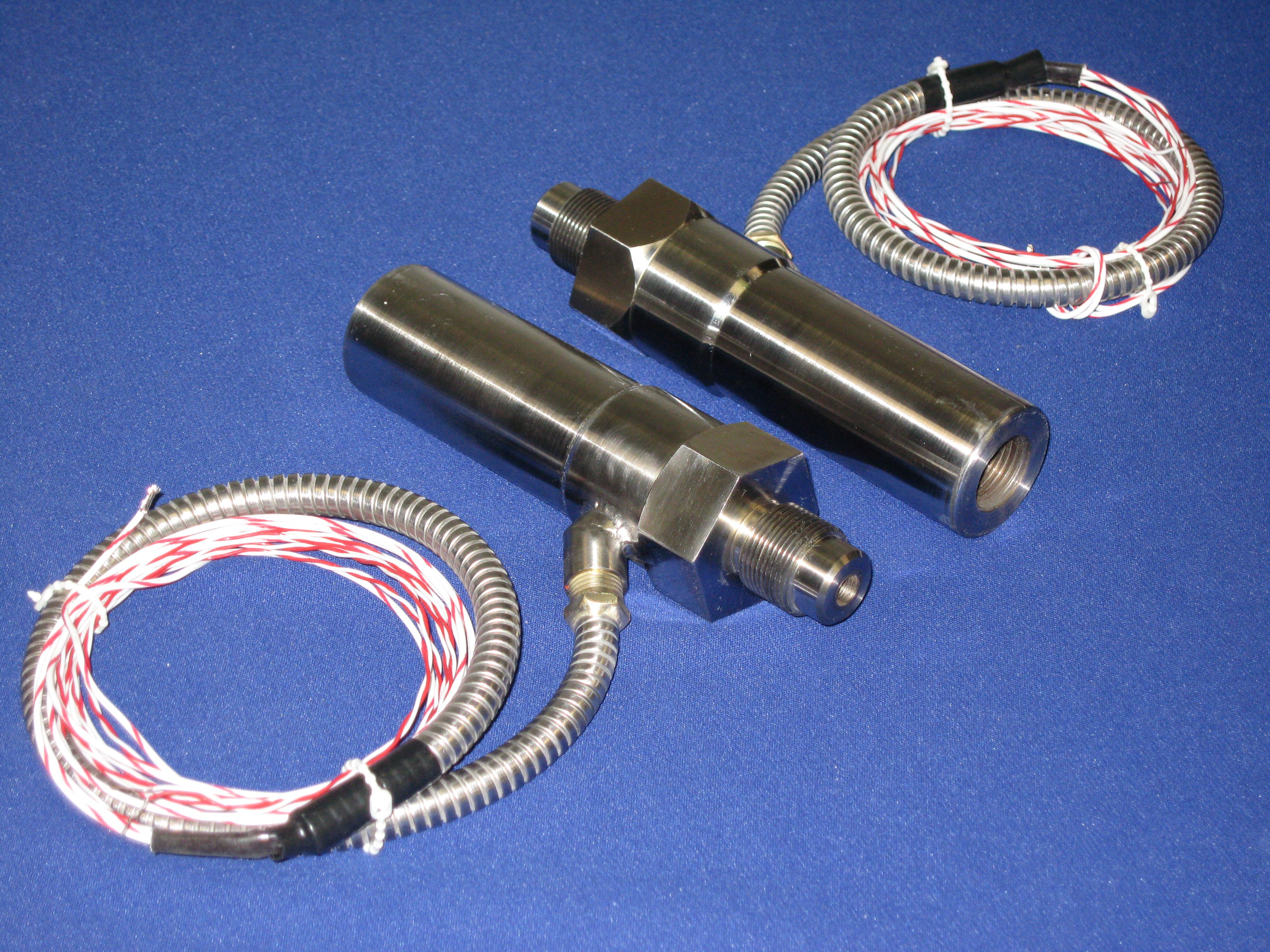

“SOLUTION” Machine Nozzles feature a built-in thermowell equipped with a choice of removable type “J” or “K” mineral insulated thermocouples. The removal feature permits the use of alternate calibration and junction types as well as providing for the replacement of damaged thermocouples. The low maintenance construction is available in range of materials satisfying the needs of both general purpose and engineering grade resins and features replaceable power leads. The integral heated “SOLUTION” Machine Nozzle is an incredibly compact, high strength nozzle capable of reliable performance under the most severe operating conditions. The high performance construction improves process cycle, reduces down time and provides maintainence free service for more cost effective processing.

Duratherm is currently manufacturing the machine nozzle components in configurations and power ratings suitable for direct replacement of existing nozzles in both plastics and diecasting machine applications. Companion accessories including nozzle tips and closed-loop control systems are also available. Our exclusive integral heated machine nozzle construction provides the performance, reliability and precision for all machine nozzle applications.