Duratherm’s combination of runnerless component design expertise, advanced machining capabilities, and in house manufactured high performance cable heaters provides the means of manufacturing a wide array of custom mold components, replacement components for obsolete systems.

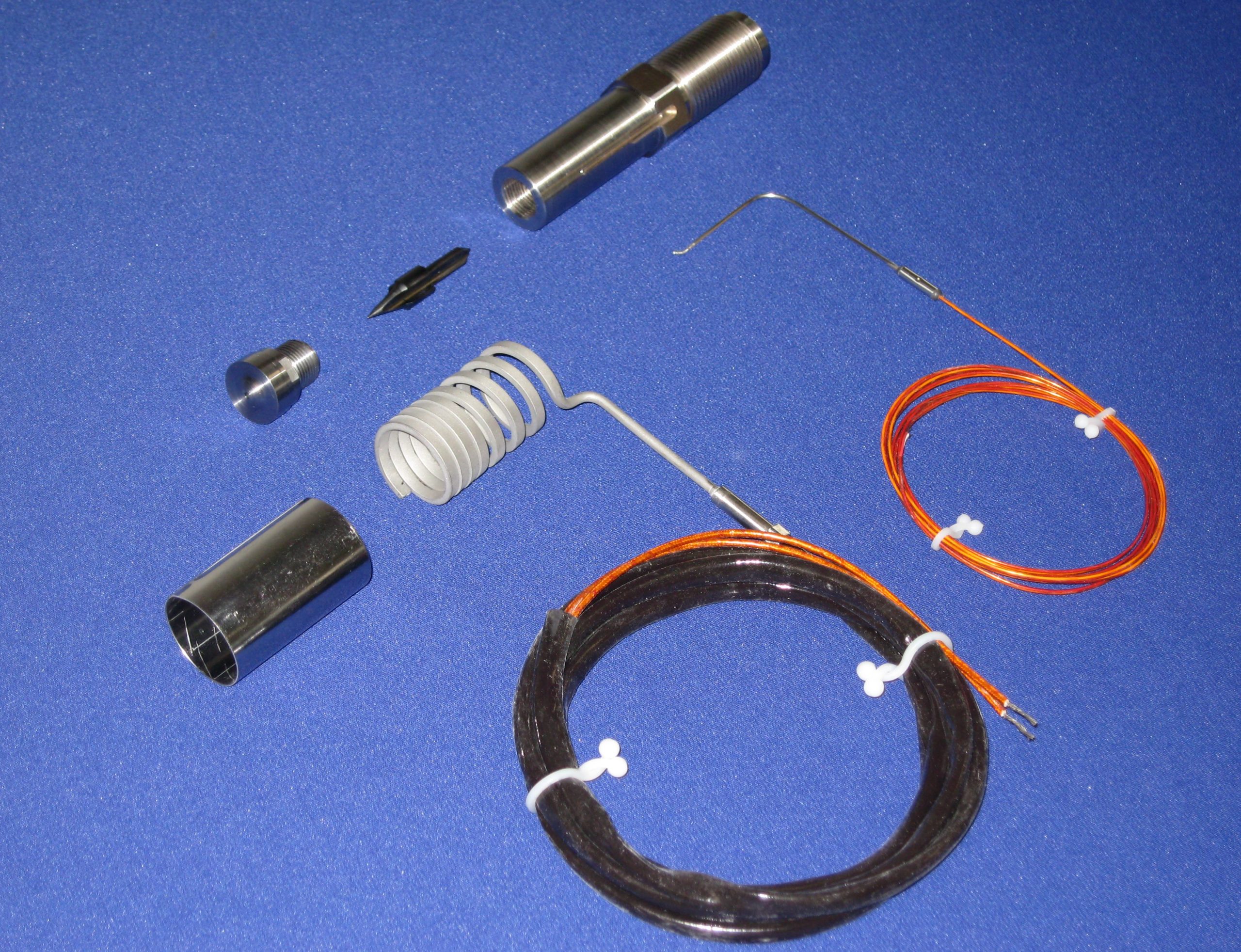

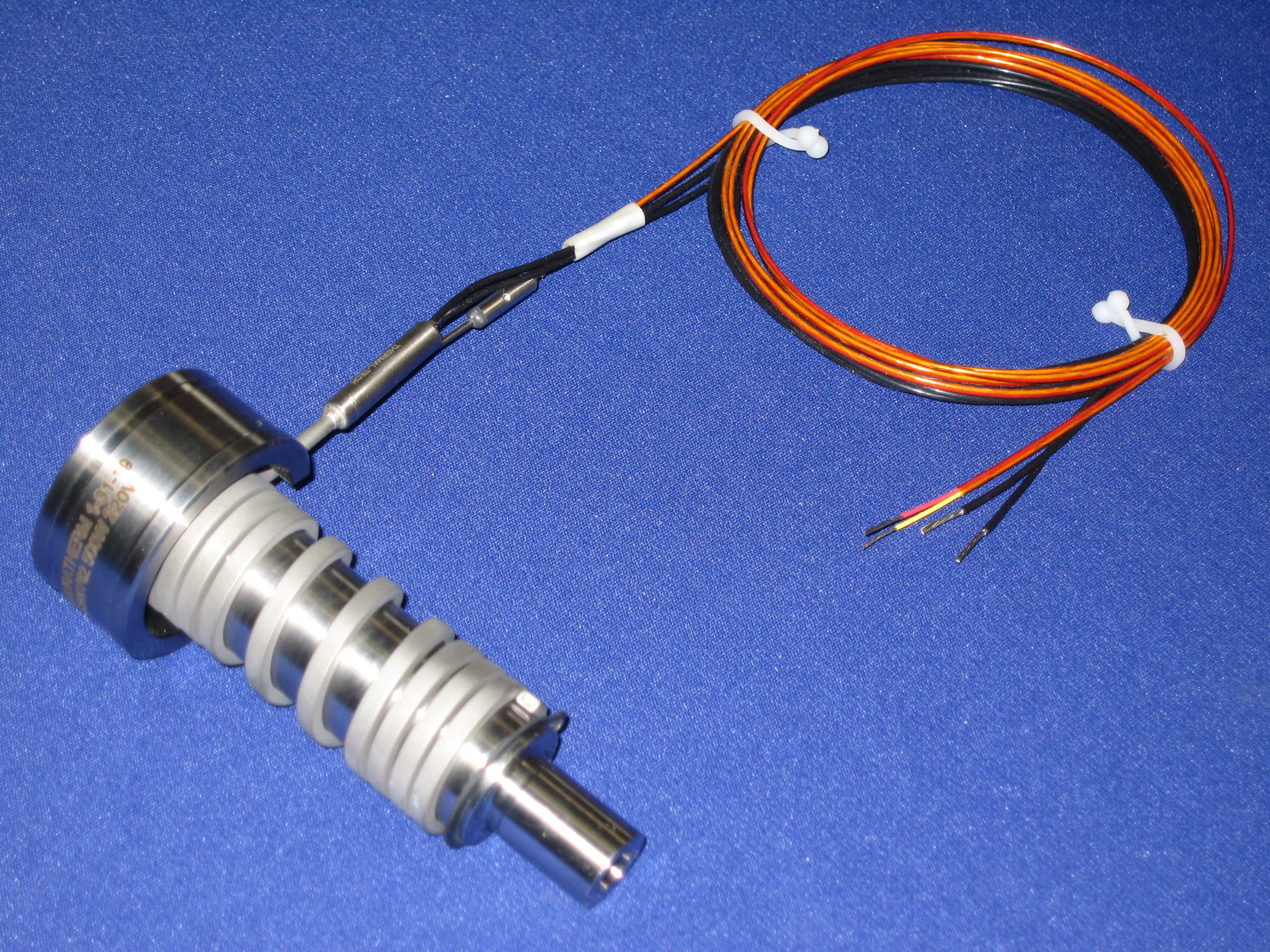

Various versions of components can be produced utilizing surface mounted and embedded cable heaters manufactured in various round, square and rectangular cross sectional constructions .

“MAXPAK” cable heaters feature precision wound parallel coil elements fusion welded to nickel cold pins. The element assemblies are embedded within high purity ceramic and encased in an oxidation resistant metal sheath. The cable heaters are swaged to the required rectangular, square or round cross-sectional dimensions to compact the internal ceramic core and ceramic insulation to near theoretical density. This high density construction maximizes heat transfer and dielectric properties and provides the high level of reliability and performance required for even the most demanding of applications.

High performance coiled coiled cable configurations are engineered for cylindrical heating applications requiring any combination of high temperature, maximum wattage and abuse resistance. The coiled heaters inner and outer diameters provide a large surface area and precision fit to external or internal cylindrical surfaces. The resulting high rate of heat transfer to the component maximizes element life and efficiency. Metal sheathed construction combined with rugged lead terminations provide superior durability.

Coiled cable configurations are precision formed utilizing computerized numerically controlled coiling machines for optimum uniformity and precision.

Special cable heater design features including cold sections, distributed wattage and internal temperature sensors can be implemented when required. Lead termination options include the standard round cold extension with transition and leads with a full selection of sleeve, wire braid and armor lead protection. A variety of custom lead terminations are also available for applications with special termination requirements.